- Tool: Use general woodworking tools, electric drill, self drill, countersink, sawing machine…

- Cutting process: Woodworking cutter speed is about 3600RPM. It needs to use tungsten carbide saw blade which diameter is 10" ~ 12" and saw tooth is 36 ~ 42 teeth, the less tooth of the blade, the easier for the machine to cut-off and discharge residue. When processing, you can spray anti rust oil (WD-40) on the saw blade to avoid crumbs with sticky.

- Burrs repair: You can use fine sandpaper, knives or scissors to grind or scrape for cutting off the burrs.

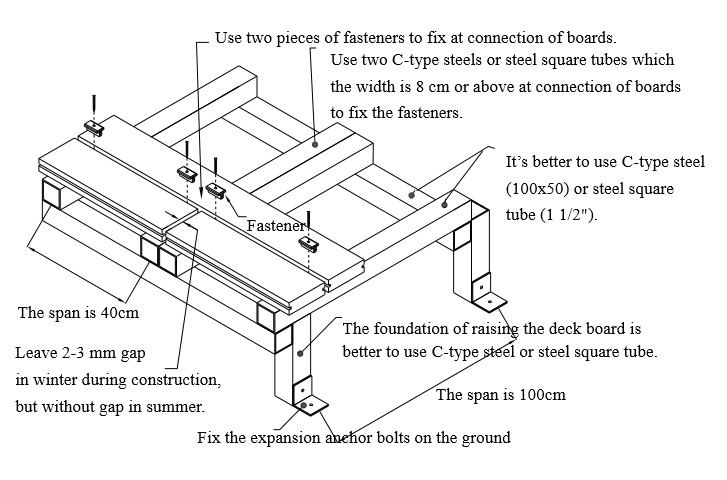

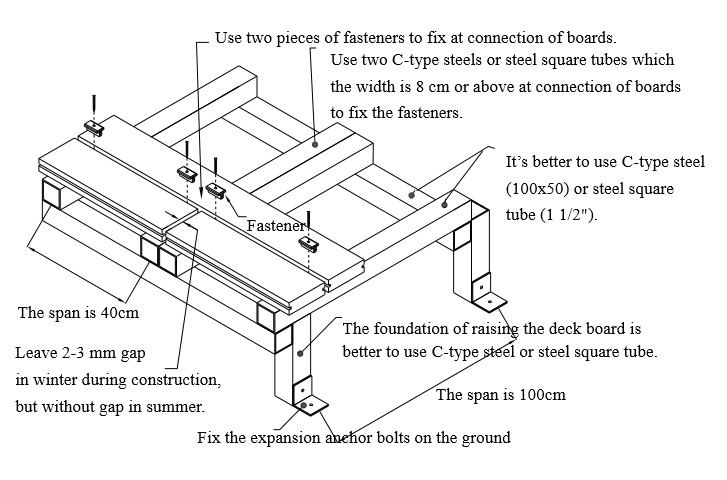

- Foundation: With C-type steel (100x50-2.3 mm thick) or steel square tube (1 1/2 "- 2 mm thick) is the best. The thickness of deck board is more than 2.5 cm: the interval between the crossbeams is 40 cm. The thickness of deck board is more than 2 cm: the interval between the crossbeams is 30-35 cm. (See the picture above) If it is flat, crossbeam can be directly fixed on the ground.

- Fasteners floor fixed method: Need to use screws, do not use nail gun or nails to fix. Steel structure base with tapping screw, decking foundation use wood screws; Screw specifications for #8 (diameter is about 4.2 mm), the length of the screw should be 2-3 cm longer than fastener; It needs two pieces of fasteners to fix at connection of boards. Also, it needs to be left 2-3 mm gap in winter, but without the gap in summer.

- Maintenance: Wipe it with water or wood floor cleaner.

- Fasteners floor construction tools as below picture:

|

|

|

|

|

| Wood screw |

Tapping screw |

saw blade |

saw blade |

Electric drill |

|