- Tool: Use general woodworking tools, electric drill, self drill, countersink, sawing machine…

- Cutting process:Woodworking cutter speed is about 3600RPM. It needs to use tungsten carbide saw blade which diameter is 10" ~ 12" and saw tooth is 36 ~ 42 teeth, the less tooth of the blade, the easier for the machine to cut-off and discharge residue. When processing, you can spray anti rust oil (WD-40) on the saw blade to avoid crumbs with sticky.

- Burrs repair: You can use fine sandpaper, knives or scissors to grind or scrape for cutting off the burrs.

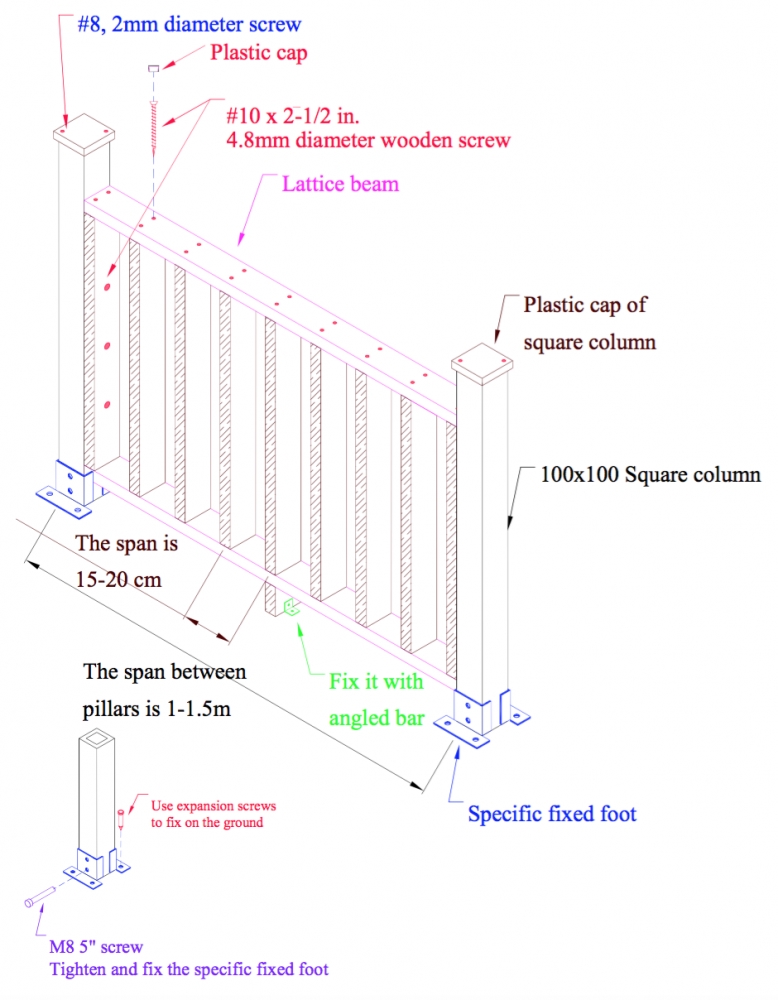

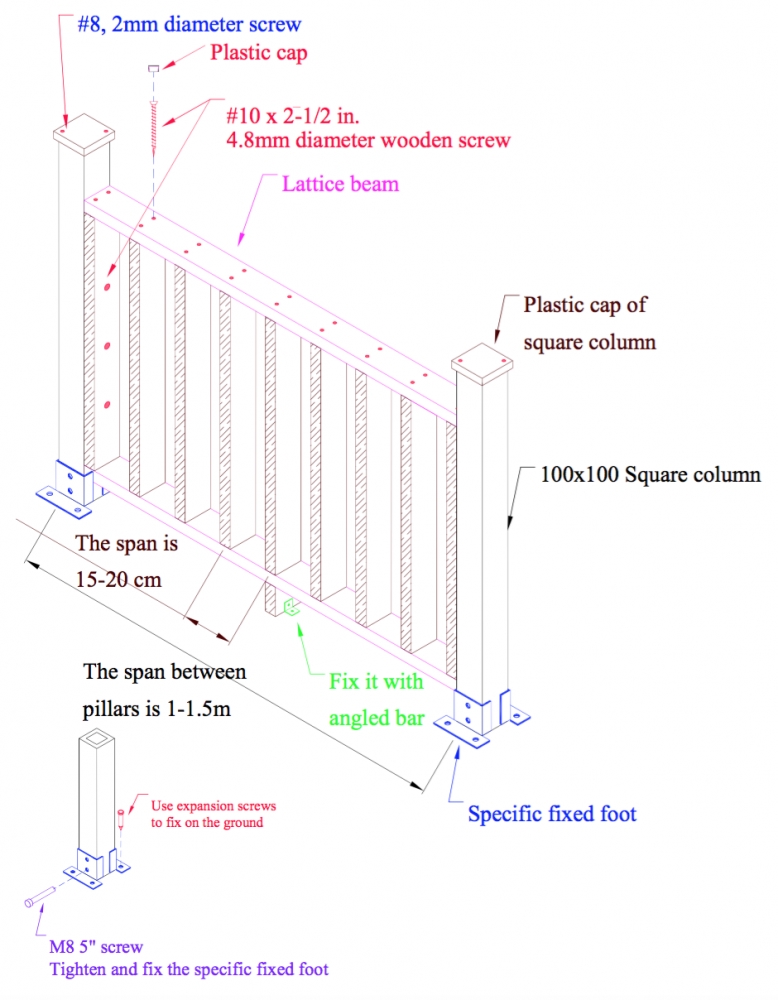

- Pillar:Use the 100x100 square column and the interval between the pillar is around 1 m to 1.5 m with specific fixed foot. Using the M8×5” screw and nut to fix the square column, then using expansion screws fixed on the ground 【See the picture below】When fixing the screws, you also can use the plastic cap to hide the screws and nuts.

- Lattice: Use the 100x40 board and the interval between each one is around 15-20 cm. (See the picture above)

- Lattice beam: Use 100x40 board as a beam to fix the lattice with #10 x 2-1/2 in., the diameter of 4.8 mm screw.

- Maintenance: Wipe it with water or wood floor cleaner.

- Rail construction tools as below picture:

|

|

|

|

|

| Wood screw |

Tapping screw |

saw blade |

saw blade |

Electric drill |

|